- DUMMY TEXT

- Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards - Limitless colour options

- Low maintenance

- Strong & durable

- Cost effective solution

- Ease of installation

- Perfect for replacement of non-compliant spandrels

- Panels can be fitted into Structural Glazing systems

Blog Archives

ULT 4 Insulated Spandrel Panels

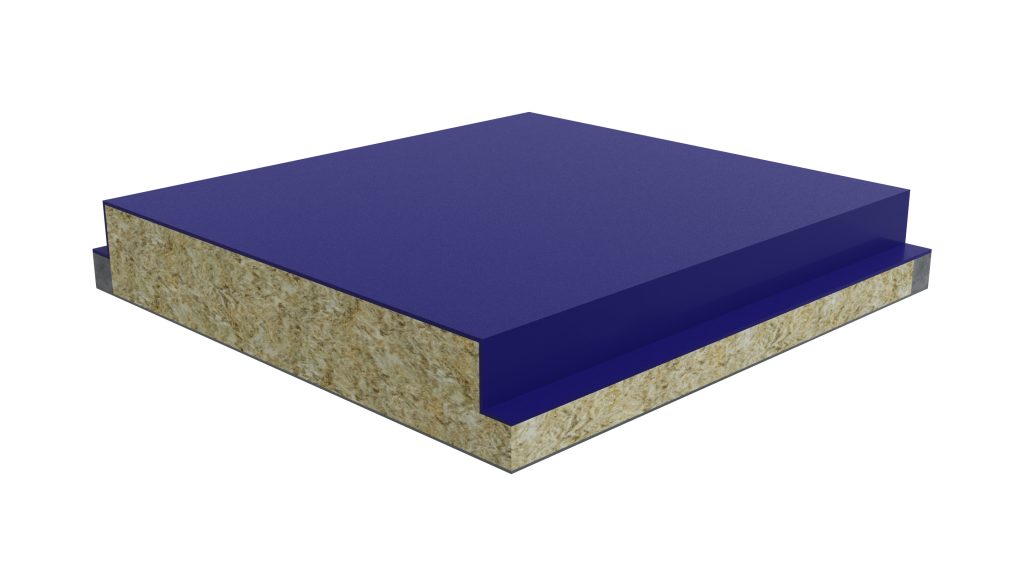

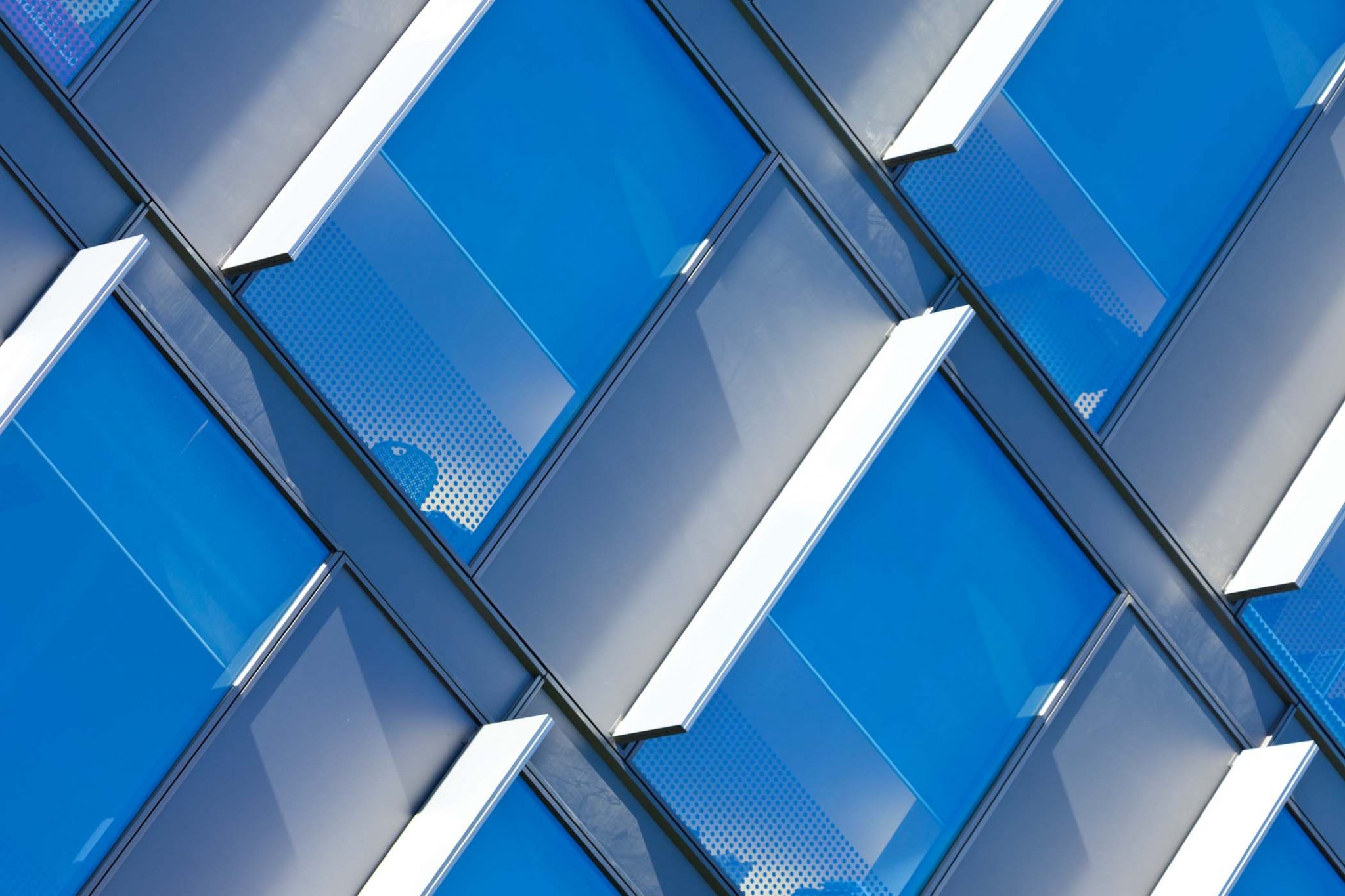

ULTIMA 4 Insulated Spandrel Panels

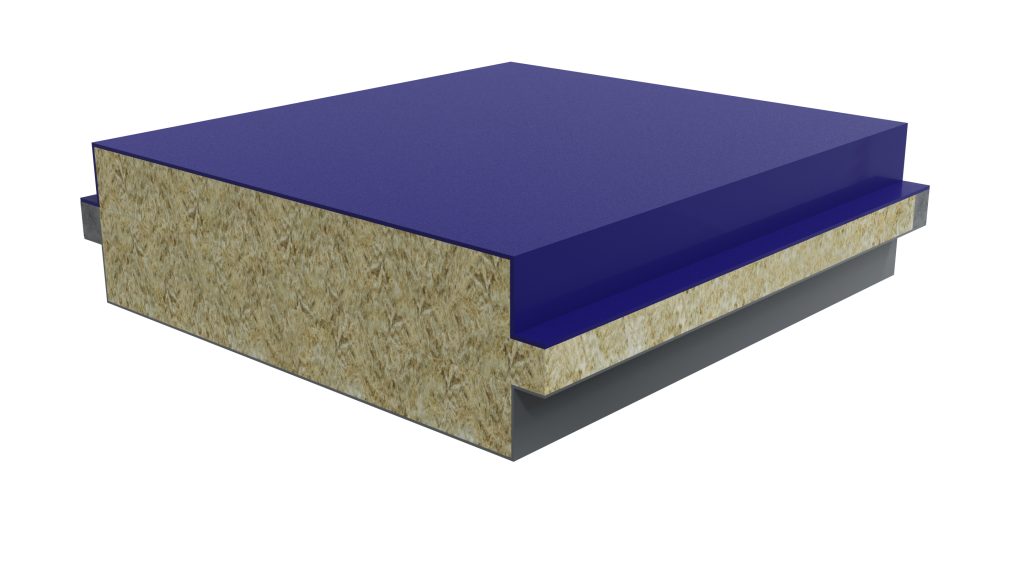

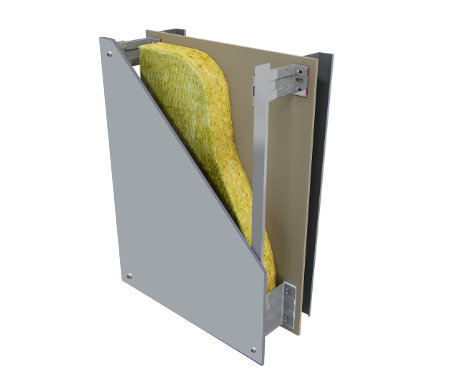

Available in either A1 or A2-s1,d0 options, the ULTIMA 4 is constructed to achieve fire compliance and structural performance plus offer designers the tools they need to meet specific project requirements. Adopting a stepped tray to the outer allows for increased amounts of insulation to be used to improve the panels thermal performance whilst maintaining the desired glazing edge thickness.

To achieve an A1 classification, an outer anodised tray is used, mechanically fixed to an inner aluminium sheet. The core is filled with high density mineral wool insulation and the two aluminium skins are separated by a perimeter thermal break.

An A2-s1,d0 rated ULTIMA 4 panel offers a powder coated outer aluminium tray, a powder coated or mill finished aluminium inner or the option of a pre-galvanised steel inner sheet. The outer tray and inner sheet are vacuum bonded to a FABROCK Insulation core and an ULTIMA A1 hard edge can be used to strengthen the perimeter of the panel.

Product Features

ULTIMA A1 NBS:

ULTIMA A2 NBS:

Technical

Downloads

ULTIMA Brochure

Technical Data Sheet

ULTIMA A1 Certification

ULTIMA A2 Certification

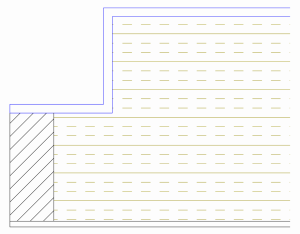

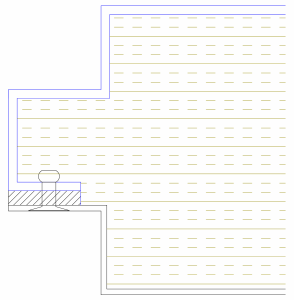

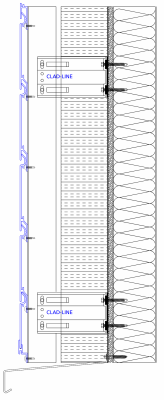

ULTIMA 4

Technical Drawing

Contact Us

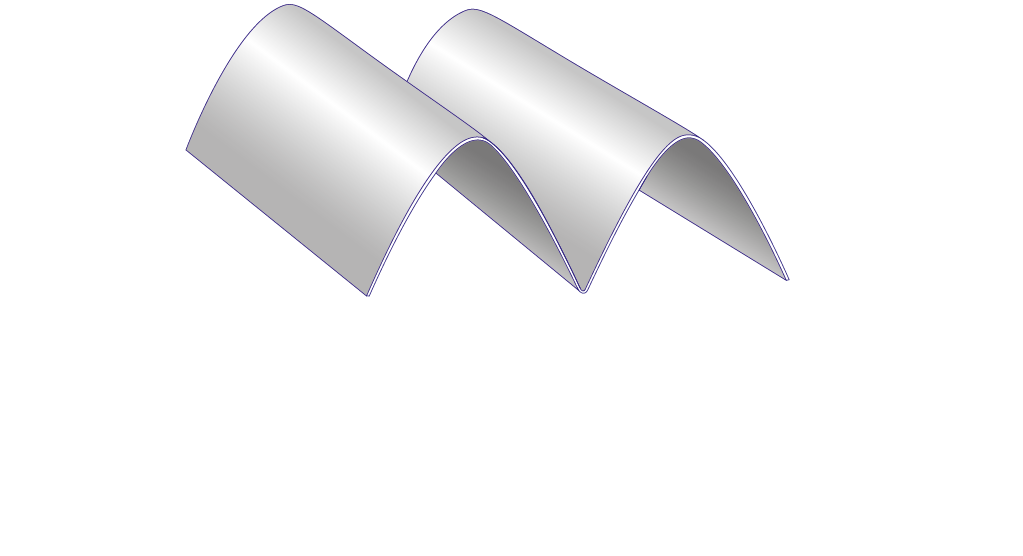

ULT 5 Insulated Spandrel Panels

ULTIMA 5 Insulated Spandrel Panels

Available in either A1 or A2-s1,d0 options, the ULTIMA 5 is constructed to achieve fire compliance and structural performance plus offer designers the tools they need to meet specific project requirements. Adopting a stepped tray to the outer and inner allows for increased amounts of insulation to be used to improve the panels thermal performance whilst maintaining the desired glazing edge thickness.

To achieve an A1 classification, an outer anodised tray is used, mechanically fixed to an inner aluminium tray. The core is filled with high density mineral wool insulation and the two aluminium skins are separated by a perimeter thermal break.

An A2-s1,d0 rated ULTIMA 5 panel offers a powder coated outer aluminium tray and a powder coated or mill finished aluminium inner tray. The outer and inner trays are vacuum bonded to a FABROCK Insulation core and an ULTIMA A1 hard edge can be used to strengthen the perimeter of the panel.

Product Features

- DUMMY TEXT

- Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards - Limitless colour options

- Low maintenance

- Strong & durable

- Cost effective solution

- Ease of installation

- Perfect for replacement of non-compliant spandrels

- Panels can be fitted into Structural Glazing systems

ULTIMA A1 NBS:

ULTIMA A2 NBS:

Technical

Downloads

ULTIMA Brochure

Technical Data Sheet

ULTIMA A1 Certification

ULTIMA A2 Certification

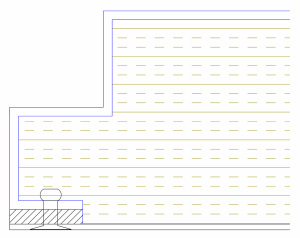

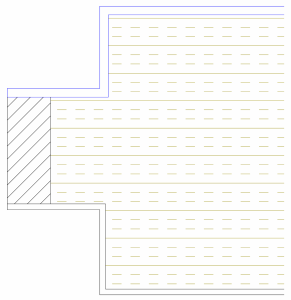

ULTIMA 5

Technical Drawing

Contact Us

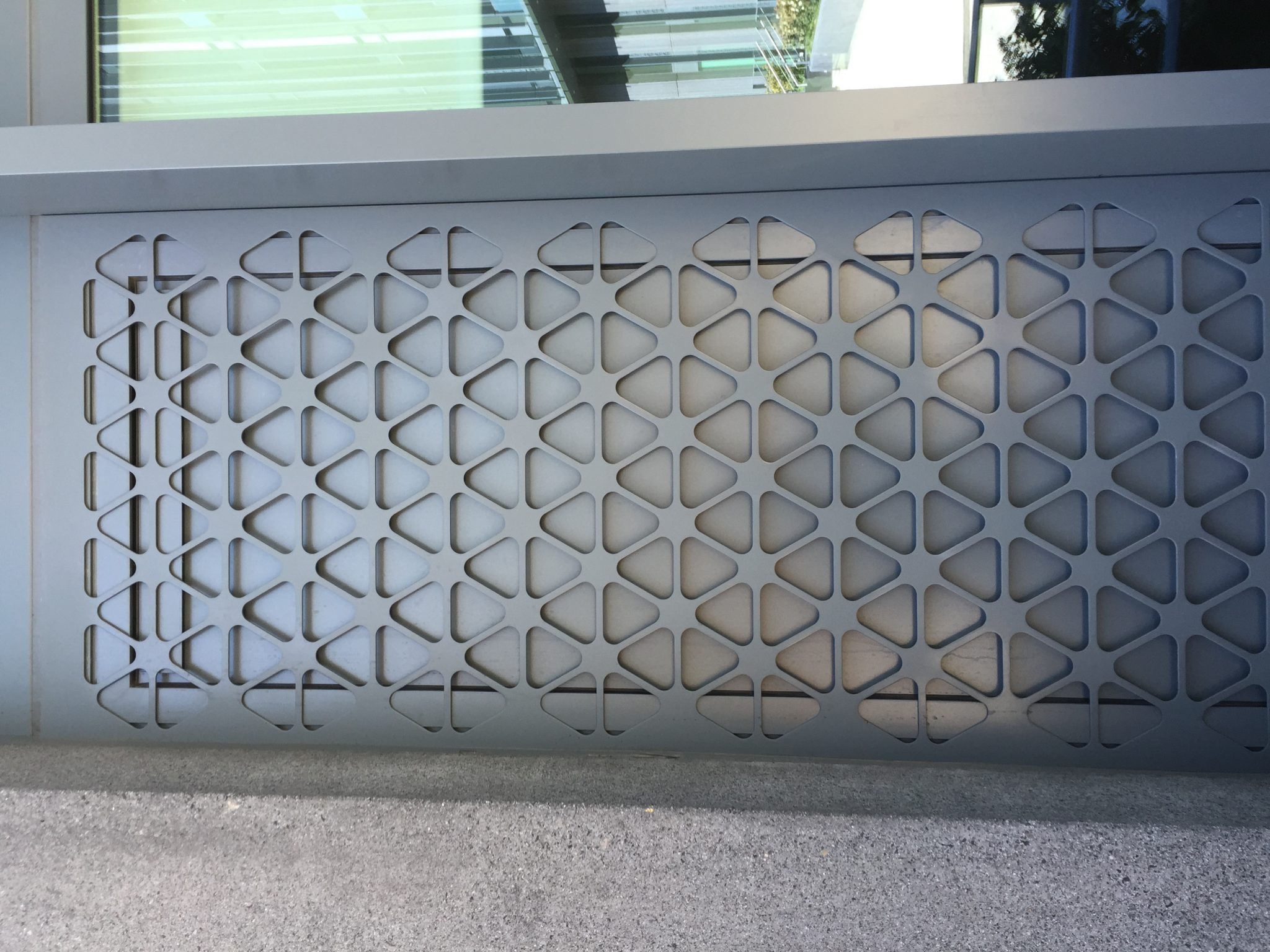

UNITY PS Interlocking Plank & Soffit System

UNITY PS Interlocking Plank & Soffit System

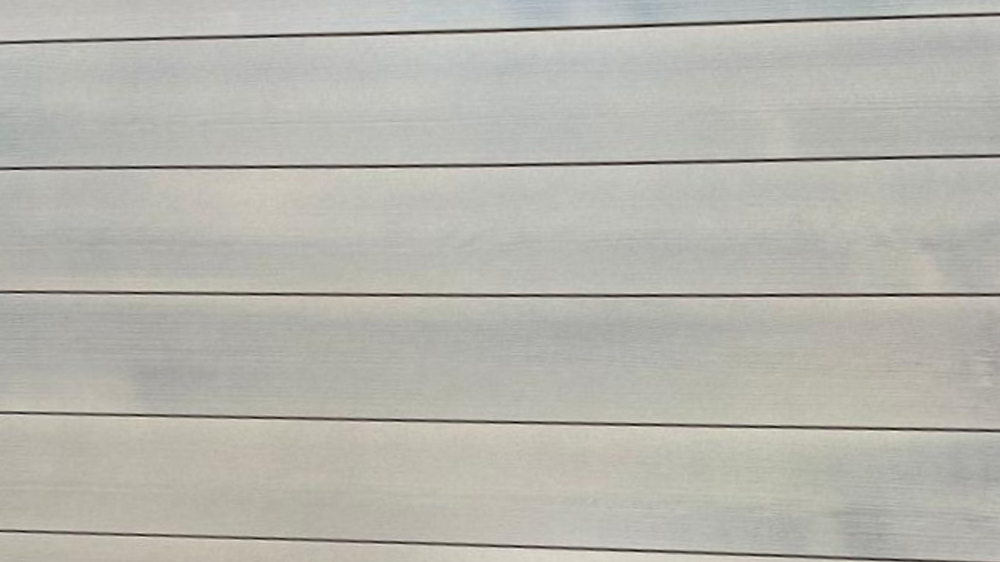

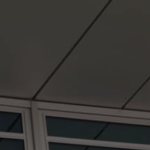

A non-combustible interlocking pressed plank which can be used as either a cladding panel or soffit system.

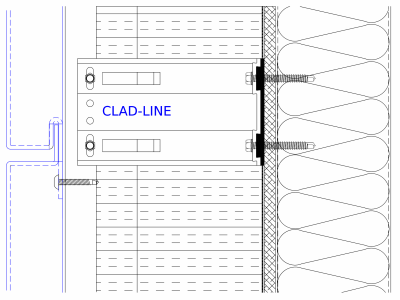

UNITY PS offers an easy to install secret fixed system for vertical face cladding or horizontal soffits. The versatile pressed plank can be supported by the CLAD-LINE CL1, F2F framing or the CL1-S soffit system. Available in anodised or powder coated aluminium, the UNITY PS system has been rigorously tested to verify both fire and structural performance.

Product Features

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Colour options

- High resistance to UV

- Strong and durable

- Ease of installation

- No visible fixings

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

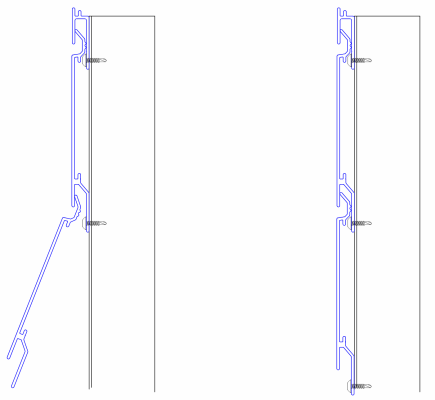

UNITY PS

Horizontal Joint

UNITY PS

Soffit Return

UNITY PS

External Corner

UNITY PS

Internal Corner

UNITY PS

Cill Interface

UNITY PS

Glazing Head Interface

UNITY PS

Capping Interface

UNITY PS

Jamb Interface

UNITY PS

Soffit System

ULTIMA Brochure

NBS Source

Contact Us

UNITY X-TRU Extruded Plank System

X-TRU Extruded Plank System

An extruded aluminium plank system which offers the ultimate in flatness and precision.

X-TRU, produced from extruded 6063-T6 aluminium, offers an interlocking, secret fixed cladding solution. Combined with fast-track installation, the inherent properties of the extruded aluminium plank deliver an ultra-flat and accurate cladding panel and is available in both anodised and powder coated finishes. X-TRU can be installed both horizontally and vertically and can be supported using the CLAD-LINE CL1, CL1-HA or Floor 2 Floor Framing System.

Features & Benefits

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Seamless design

- Independently tested & certified to Fire Safety classifications

- Accurate & Robust

- Multitude of finishing options available

Timber/Wood Grain effect, PPC and Anodised. - Variety of lengths available

- Installed Horizontally or Vertically

- Recyclable

- Easy to install & secret fix

UNITY X-TRU A1 NBS:

UNITY X-TRU A2 NBS:

Technical

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

X-TRU D01

Vertical Joint

X-TRU D02

Horizontal Joint

X-TRU D03

External Corner

X-TRU D04

Internal Corner

X-TRU D05 Window

Cill Detail

UNITY X-TRU

Technical Information

UNITY X-TRU

Technical Information

Gallery

Contact Us

Archives

Meta

Metalline (Services) Ltd,

Hollies Park Road,

Cannock,

Staffordshire,

WS11 1DB