- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Colour options

- High resistance to UV

- Strong and durable

- Ease of installation

- Available in landscape and portrait

panel orientation

Blog Archives

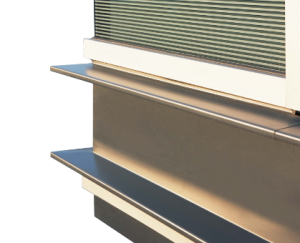

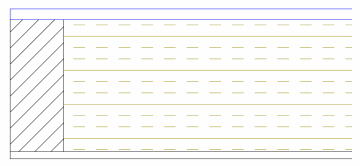

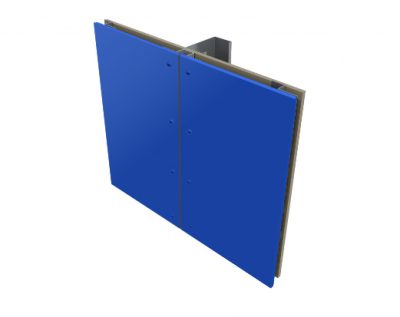

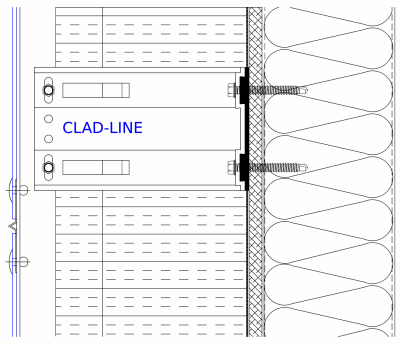

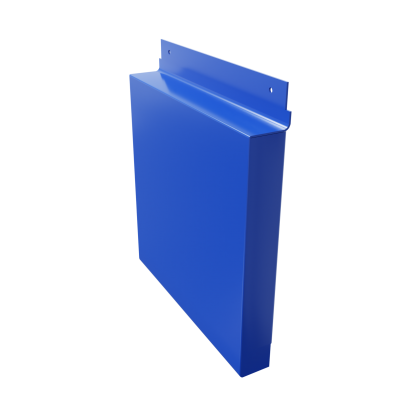

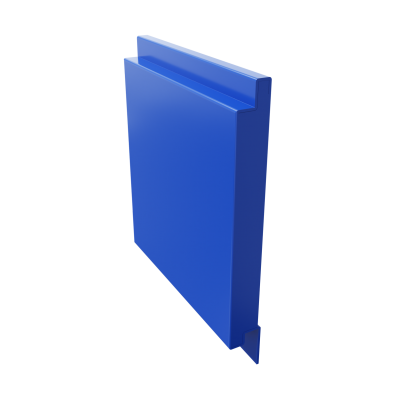

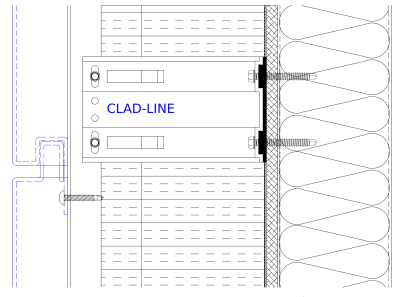

UNITY DF Discrete Fix Rainscreen System

UNITY DF Discrete Fix Rainscreen System

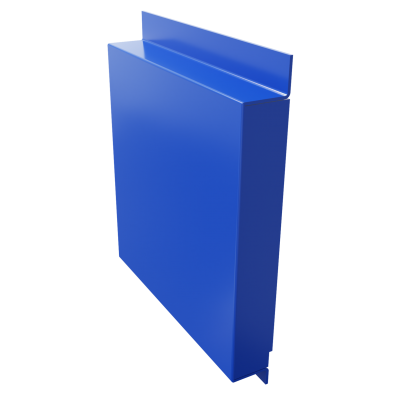

A versatile non-combustible rainscreen cassette system available in both landscape and portrait orientation. Colour matched fixings located in the recessed shadow joint provide a streamlined aesthetic.

UNITY DF offers an easy to install cladding solution which can be supported by either the CLAD-LINE CL1 or Floor 2 Floor Framing System. Available in anodised, pre-coated or powder coated aluminium, the UNITY DF system has been rigorously tested to verify both fire and structural performance.

Product Features

UNITY DF A1 NBS:

UNITY DF A2 NBS:

Technical

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

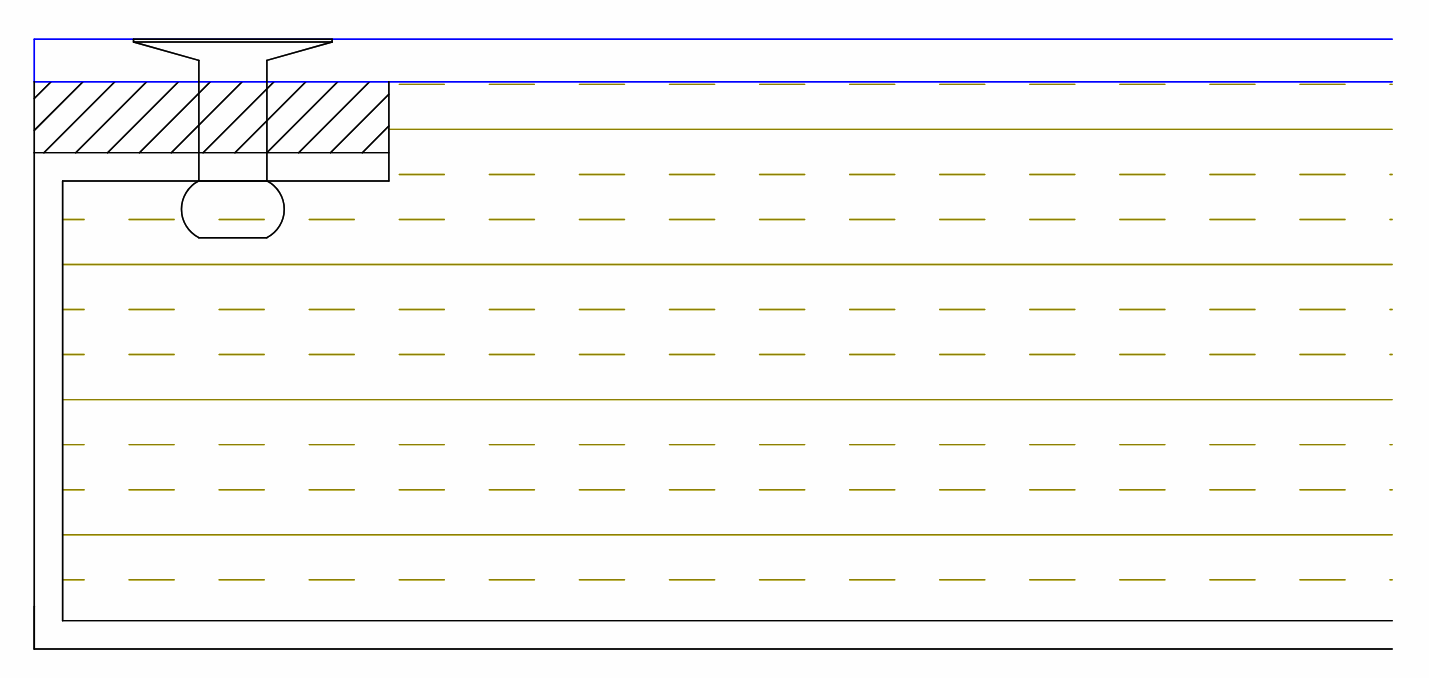

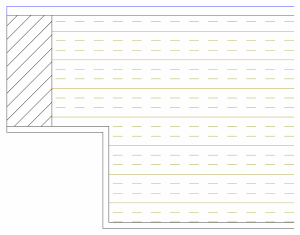

UNITY DF

Horizontal Joint

UNITY DF

Soffit Return

UNITY DF

External Corner

UNITY DF

Internal Corner

UNITY DF

Cill Interface

UNITY DF

Glazing Head Interface

UNITY DF

Jamb Interface

UNITY DF

Vertical Joint

UNITY DF A1

NBS Source

UNITY DF A2

NBS Source

Contact Us

General Pressings

Pressings

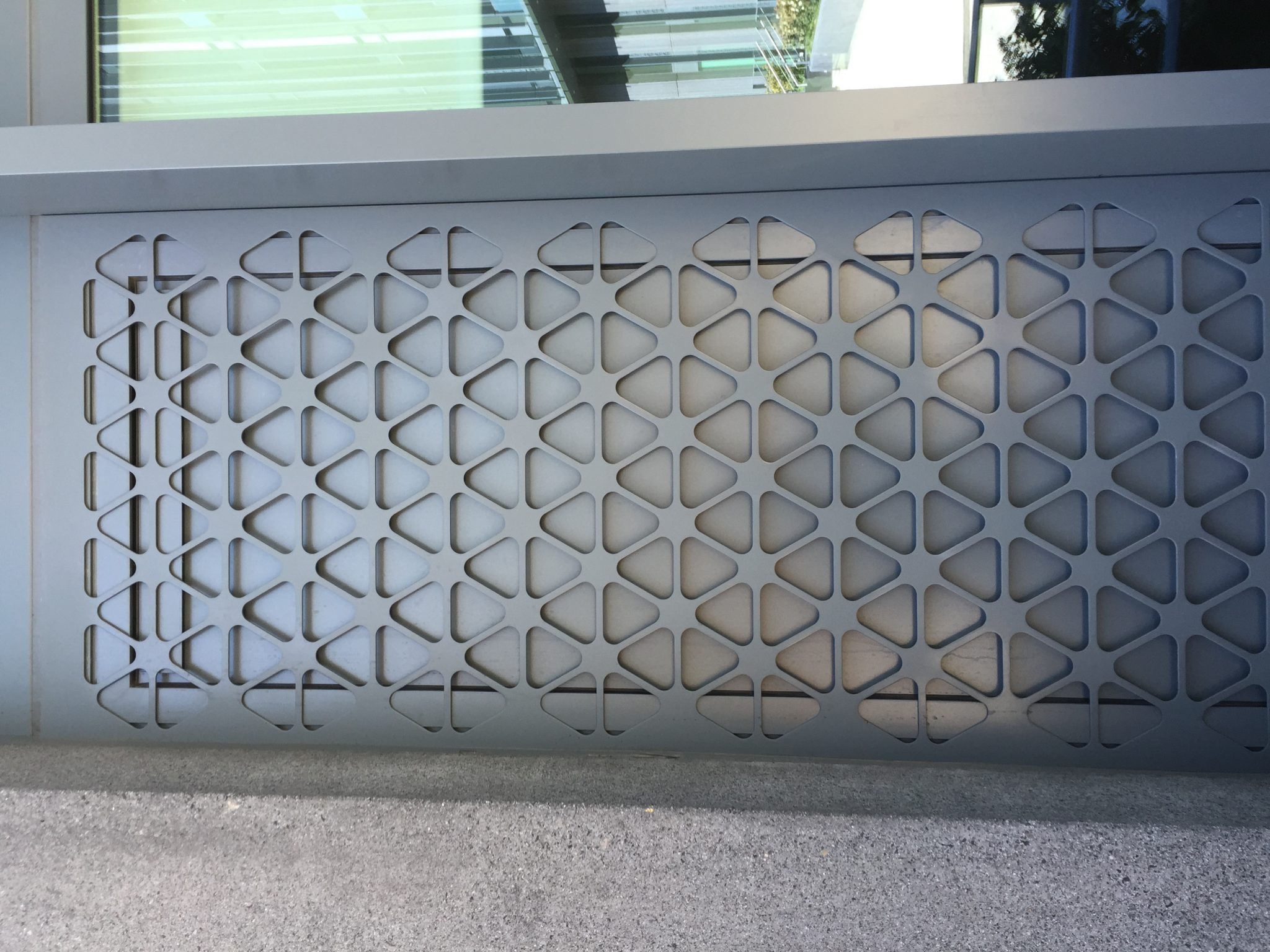

Metalline has been at the forefront of producing bespoke architectural aluminium pressings for over three decades, offering unparalleled expertise in crafting tailored solutions to meet your precise requirements.

All our copings feature a discreet fix system, ensuring a secure mounting without compromising the visual integrity of your design. Available in various finishes, including standard mill finish, ANOLOK anodising, or bespoke powder coating, our copings provide both functionality and elegance.

Neglecting to install copings can leave your building vulnerable to water damage. Our aluminium copings create a weatherproof seal, safeguarding the top layer of your walls and preventing costly repairs down the line.

Why Choose Metalline for Your General Pressings?

At Metalline, we understand the importance of every detail in your project. Our range of General Pressings, including copings, cills, fins, and various architectural elements, seamlessly integrates functionality with aesthetic appeal, elevating the visual impact of your building’s facade.

Key Features of Metalline’s General Pressings:

- Extensive Design Catalogue: Leveraging our extensive design repository, we empower specifiers and designers to achieve their desired finish effortlessly. Whether it’s window pods, cruciforms, or bird beak panels, we offer a diverse selection to enhance the external envelope of any structure.

- Bespoke Solutions: Tailored to your specifications, our products encompass a wide array of fabricated panels and aluminium pressings, not only for external facades but also ideal for enhancing internal spaces such as stairwells and escalators.

- Finish Options: All our products are available in either anodised or polyester powder coated finishes, ensuring durability and aesthetic consistency across projects.

With Metalline, you can expect unparalleled craftsmanship, attention to detail, and a commitment to delivering solutions that exceed expectations.

Contact our team today to explore the possibilities and discover how we can elevate your project to new heights.

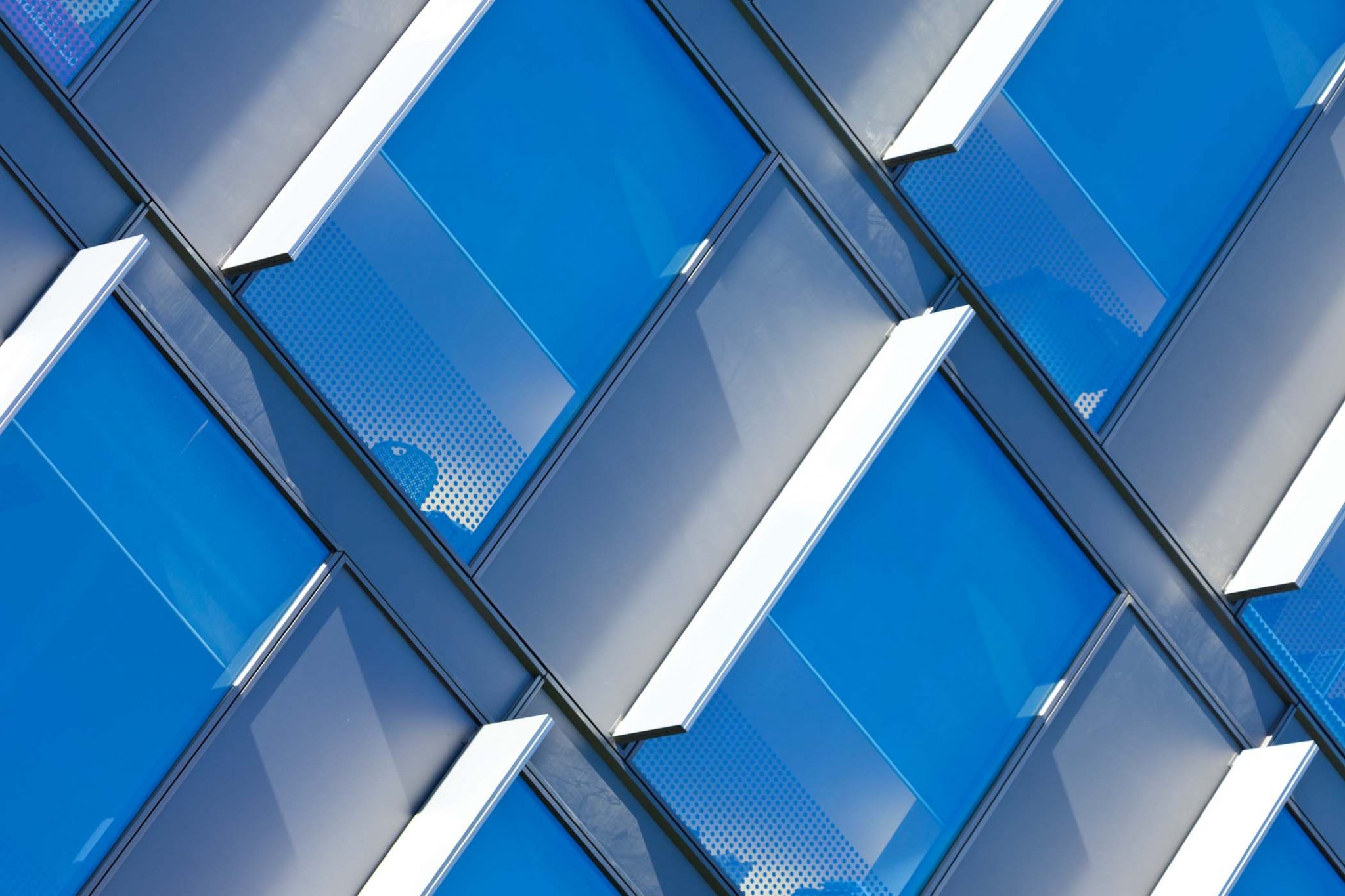

Feature Beam

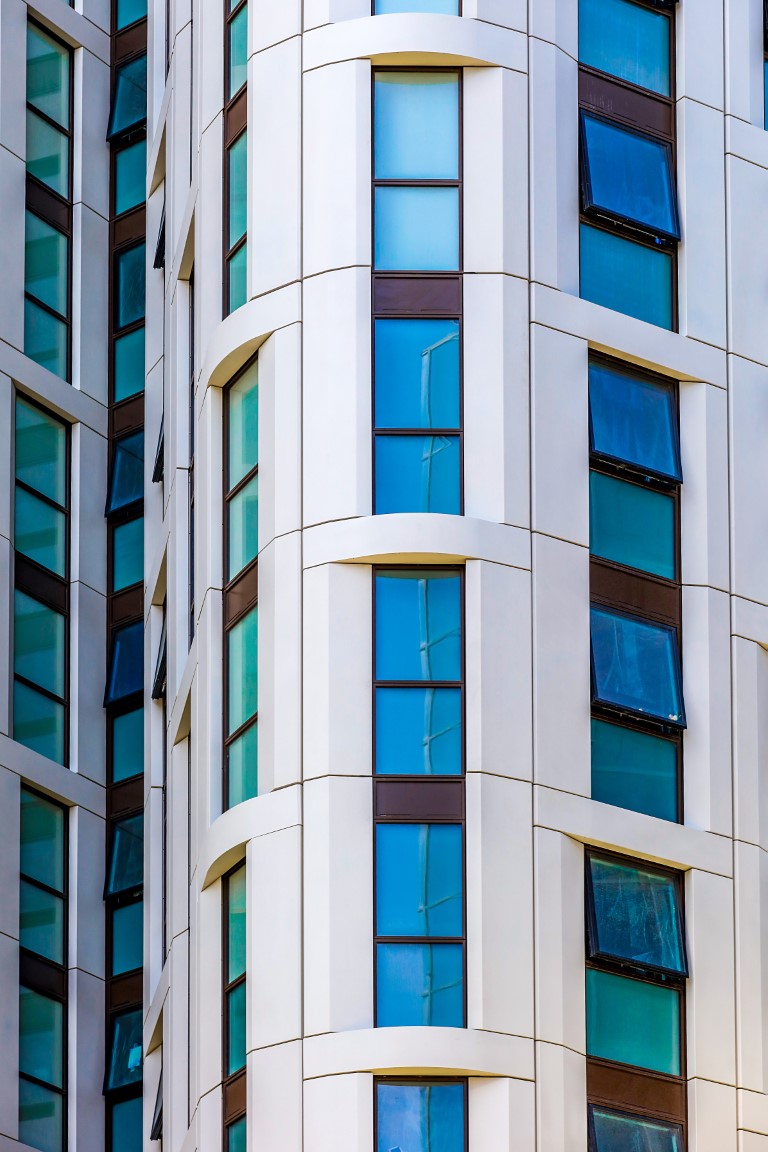

Feature Beam is a highly adaptable metal pressing that can be used in conjunction with most curtain walling and cladding systems to provide a unique exterior finish to any building.

Feature Beam is an aluminium or stainless steel pressing which is available in a variety of finishes. These include polyester powder coated, anodised or polished.

To find out more about Feature Beam, please click here.

Gallery

Contact Us

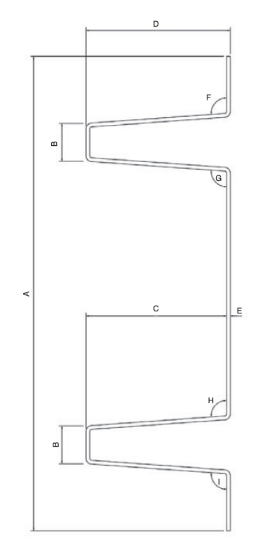

Feature Beam

Feature Beam

Feature Beam is a highly adaptable metal pressing that can be used in conjunction with most curtain walling and cladding systems to provide a unique exterior finish to any building.

Feature Beam is an aluminium or stainless steel pressing which is available in a variety of finishes. These include polyester powder coated, anodised or polished.

Product Features

FEATURE BEAM NBS:

Technical

A – Minimum approx 150mm Max approx 1500mm

B – Minimum 17mm providing one of the F/G or H/I is 970. Increase if all angles are 900. This is based on 2mm thickness, increases if 3mm

C – Generally 75mm

D – Minimum 15mm, Maximum approx 2000mm

E – Generally 2mm, Occasionally 3mm

F – Generally 97° , can alter to suit

G – Generally 97°, can alter to suit

H – Generally 97°, can alter to suit

I – Generally 97°, can alter to suit

Downloads

Technical Details Overview

Feature Beam Technical Drawing

Technical Curtain Wall Fitting 1

Technical Curtain Wall Fitting 2

Curtain Walling/Soffit Fitting

Wall Fitting

Wall Cladding Panels Fitting

Terracotta Rainscreen Fitting

NBS Source

Gallery

Contact Us

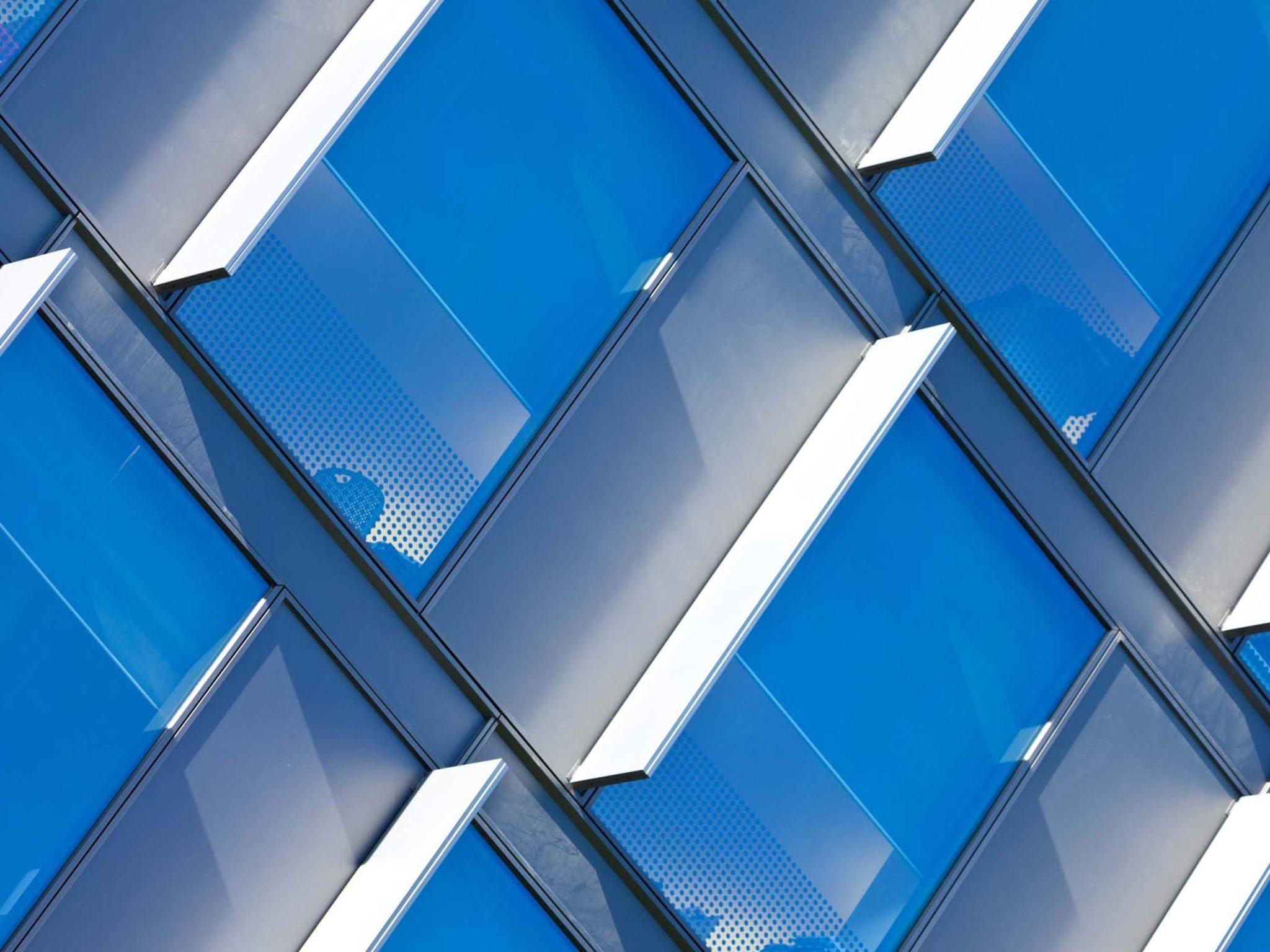

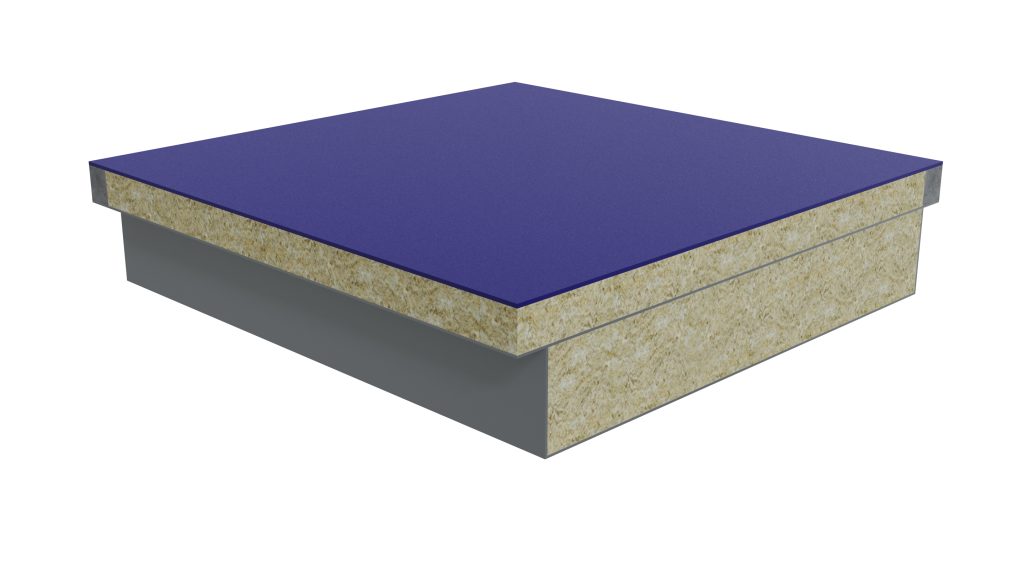

ULTIMA ULT 1

ULTIMA Insulated Spandrel Panels

Available in either A1 or A2-s1,d0 options, the ULTIMA 1 is constructed to achieve fire compliance and structural performance plus offer designers the tools they need to meet specific project requirements.

To achieve an A1 classification, an outer anodised sheet is used, mechanically fixed to an inner aluminium tray. The core is filled with high density mineral wool insulation and the two aluminium skins are separated by a perimeter thermal break.

An A2-s1,d0 rated ULTIMA 1 panel offers a powder coated outer aluminium sheet, a powder coated or mill finished aluminium inner or the option of a pre-galvanised steel inner sheet. The outer and inner sheets are vacuum bonded to a Fabrock Insulation core and an ULTIMA A1 hard edge can be used to strengthen the perimeter of the panel.

Product Features

- Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards - Limitless colour options

- Low maintenance

- Strong & durable

- Cost effective solution

- Ease of installation

- Perfect for replacement of non-compliant spandrels

- Panels can be fitted into Structural Glazing systems

ULTIMA A1 NBS:

ULTIMA A2 NBS:

Technical

Downloads

ULTIMA Brochure

Technical Data Sheet

ULTIMA A1 Certification

ULTIMA A2 Certification

ULTIMA 1

Technical Drawing

Contact Us

UNITY A1 TF Through Fix Rainscreen System

UNITY TF Through Fix Rainscreen System

A face fixed non-combustible solid aluminium rainscreen panel that is perfect for the replacement of existing HPL and ACM cladding panels.

UNITY TF offers an easy to install cladding solution which can be supported by either the CLAD-LINE CL1 or Floor 2 Floor Framing System. Available in anodised, pre-coated or powder coated aluminium, the UNITY TF system has been rigorously tested to verify both fire and structural performance.

Product Features

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - High resistance to UV

- Strong and durable

- Cost effective solution

- Ease of installation

- Perfect for HPL and ACM replacement panels

UNITY TF A1 NBS:

UNITY TF A2 NBS:

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

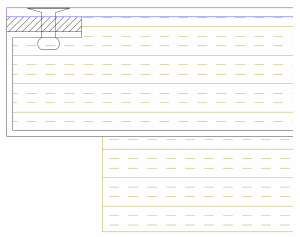

UNITY TF

Jamb Interface

UNITY TF

Glazing Head Interface

UNITY TF

Capping Head Interface

UNITY TF

Cill Interface

UNITY TF

Internal Cover

UNITY TF

Soffit Return

UNITY TF

External Corner

UNITY TF

Horizontal Joint

UNITY TF

Vertical Joint

UNITY TF A1

NBS Source

UNITY TF A2

NBS Source

Contact Us

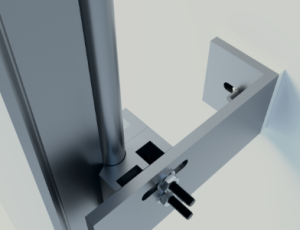

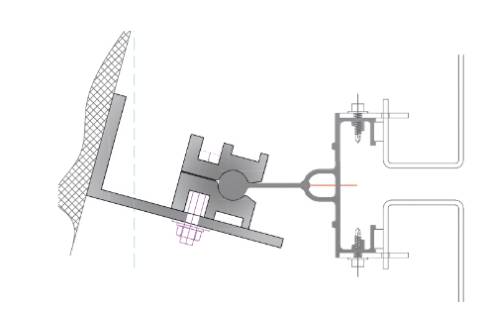

UNITY A1 F2F Rail System

UNITY Floor 2 Floor Framing System

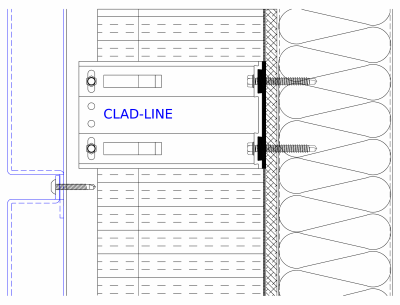

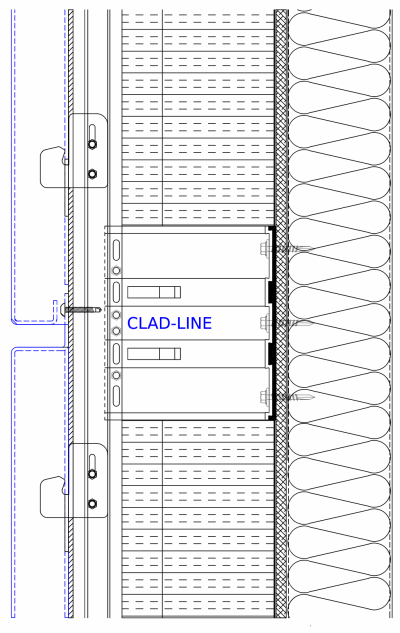

The UNITY Floor 2 Floor Framing System has been designed to accommodate, flat, discrete-fix and hook-on rainscreen panels and is fully compliant with all types of A1 and A2 facade panels including aluminium, Rockpanel, fibre cement, ACM and terracotta.

UNITY Floor 2 Floor Framing System spans from floor slab to floor slab, reducing the requirement for multiple Helping Hand brackets and supporting Top Hats. This saves considerable time and money on installation costs, simplifies the design process, allows for greater adjustment and reduces the requirement for fixings and brackets by up to 90%.

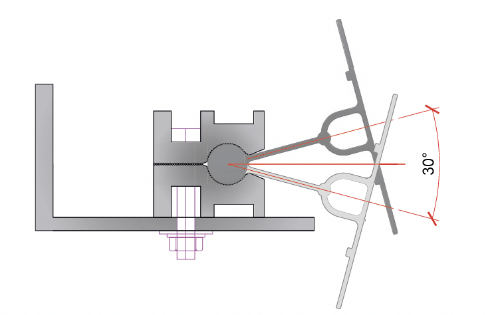

The innovative ball and socket design means the system is ideal for high rise developments and cladding replacements. The maximum amount of adjustability helps to tackle the challenges often prevalent on existing buildings.

Features & Benefits

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Simplifies design and installation

- Reduces labour costs

- Maximum adjustment in all directions

- Ideal for use with faceted facades

- Avoids fixing into non-structural infill

- Solid Aluminium - Non-combustible

- Sectional properties available upon request

Technical

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

UNITY F2F A1

NBS Source

UNITY F2F A2

NBS Source

Gallery

Contact Us

UNITY A1 SF Secret-Fix Rainscreen System

UNITY SF Secret-Fix Rainscreen System

A non-combustible “Hook-On” secret fix cassette system which provides a streamlined appearance whilst remaining quick and easy to install.

UNITY SF offers an easy to install cladding solution which can be supported by either the CLAD-LINE CL2 or Floor 2 Floor Framing System. Available in anodised, pre-coated or powder coated aluminium, the UNITY SF system has been rigorously tested to verify both fire and structural performance.

Product Features

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Colour options

- High resistance to UV

- Strong and durable

- Ease of installation

- No visible fixings

UNITY SF A1 NBS:

UNITY SF A2 NBS:

Downloads

UNITY Brochure

Technical Data Sheet

UNITY Certification

UNITY SF

External Corner

UNITY SF

Horizontal Joint

UNITY SF

Internal Corner

UNITY SF

Capping Interface

UNITY SF

Glazing Head Interface

UNITY SF

Cill Interface

UNITY SF

Jamb Interface

UNITY SF

Vertical Joint

UNITY SF A1

NBS Source

UNITY SF A2

NBS Source

Contact Us

UNITY IL Interlocking Rainscreen System

UNITY IL Interlocking Plank & Soffit System

A non-combustible interlocking pressed plank which can be used as either a cladding panel or soffit system.

UNITY IL offers an easy to install secret fixed system for vertical face cladding or horizontal soffits. The versatile pressed plank can be supported by the CLAD-LINE CL1, F2F framing or the CL1-S soffit system. Available in anodised or powder coated aluminium, the UNITY IL system has been rigorously tested to verify both fire and structural performance.

Product Features

- DUMMY TEXT

- Reaction to fire performance

Anodised aluminium – A1 classification to BS EN13501-1

Pre-coated aluminium – A1 classification to BS EN13501-1

Powder coated aluminium – A2- s1,d0 classification to BS EN13501-1 - Superior reaction to fire testing of powder coated panels

Powder coated panels tested fixed back to aluminium rails with horizontal and vertical joints, the appropriate ventilation space and a mineral wool substrate. All colours covered by the test’s Field of Application - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards for serviceability and safety - Dynamic water resistance

Fully tested to CWCT standards - Colour options

- High resistance to UV

- Strong and durable

- Ease of installation

- No visible fixings

UNITY IL A1 NBS:

UNITY IL A2 NBS:

Downloads

UNITY Brochure

Technical Data Sheet

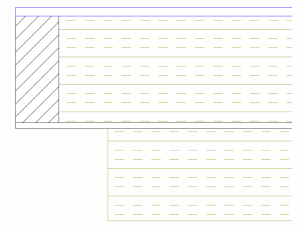

UNITY IL

Horizontal Joint

UNITY IL

Soffit Return

UNITY IL

External Corner

UNITY IL

Internal Corner

UNITY IL

Cill Interface

UNITY IL

Glazing Head Interface

UNITY IL

Capping Head Interface

UNITY IL

Jamb Interface

UNITY IL

Vertical Joint

UNITY IL A1

NBS Source

UNITY IL A2

NBS Source

Contact Us

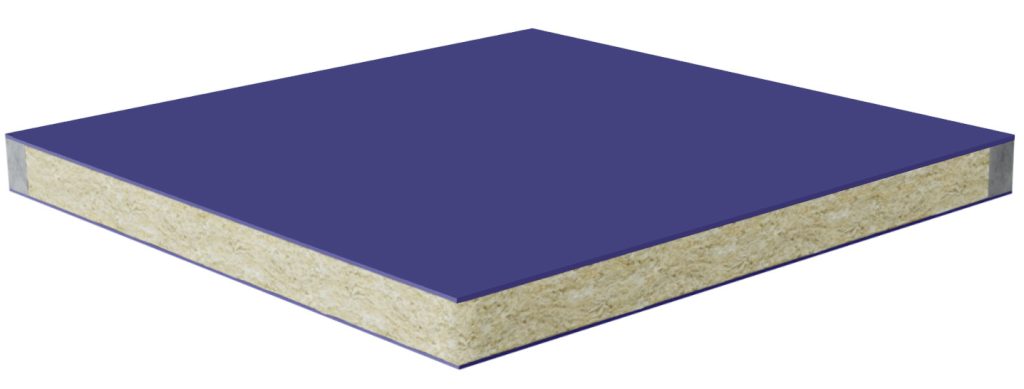

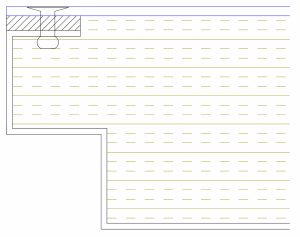

ULT 2 Insulated Spandrel Panels

ULTIMA 2 Insulated Spandrel Panels

Available in either A1 or A2-s1,d0 options, the ULTIMA 2 is constructed to achieve fire compliance and structural performance plus offer designers the tools they need to meet specific project requirements. Adopting a stepped tray to the inner allows for increased amounts of insulation to be used to improve the panel’s thermal performance whilst maintaining the desired glazing edge thickness.

To achieve an A1 classification, an outer anodised sheet is used, mechanically fixed to an inner aluminium tray. The core is filled with high density mineral wool insulation and the two aluminium skins are separated by a perimeter thermal break.

An A2-s1,d0 rated ULTIMA 2 panel offers a powder coated outer aluminium sheet, a powder coated or mill finished aluminium inner tray or the option of a pre-galvanised steel inner tray. The outer sheet and inner tray are vacuum bonded to a Fabrock Insulation core and an ULTIMA A1 hard edge can be used to strengthen the perimeter of the panel.

Product Features

- DUMMY-ITEM

- Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards - Limitless colour options

- Low maintenance

- Strong & durable

- Cost effective solution

- Ease of installation

- Perfect for replacement of non-compliant spandrels

- Available in landscape or portrait orientation

- Panels can be fitted into Structural Glazing systems

ULTIMA A1 NBS:

ULTIMA A2 NBS:

Technical

Downloads

ULTIMA Brochure

Technical Data Sheet

ULTIMA A1 Certification

ULTIMA A2 Certification

ULTIMA 2

Technical Drawing

Contact Us

ULT 3 Insulated Spandrel Panels

ULTIMA 3 Insulated Spandrel Panels

Available in either A1 or A2-s1,d0 options, the ULTIMA 3 is constructed to achieve fire compliance and structural performance plus offer designers the tools they need to meet specific project requirements. The use of ‘piggyback’ mineral wool insulation to the rear of the panel helps to improve the panel’s thermal performance whilst maintaining the desired glazing edge thickness.

To achieve an A1 classification, an outer anodised sheet is used, mechanically fixed to an inner aluminium tray. The core is filled with high density mineral wool insulation and the two aluminium skins are separated by a perimeter thermal break.

An A2-s1,d0 rated ULTIMA 3 panel offers a powder coated outer aluminium sheet, mill finished aluminium inner or the option of a pre-galvanised steel inner sheet. The outer sheet and inner sheet are vacuum bonded to a Fabrock Insulation core and an ULTIMA A1 hard edge can be used to strengthen the perimeter of the panel.

Product Features

- DUMMY TEXT

- Reaction to fire performance

A1 & A2 - s1,d0 classification to BS EN13501-1 - Impact resistance

Soft & hard body impacts fully tested to CWCT TN75/76 Standards - Wind resistance

Fully tested to CWCT standards - Limitless colour options

- Low maintenance

- Strong & durable

- Cost effective solution

- Ease of installation

- Perfect for replacement of non-compliant spandrels

- No visible fixings

- Panels can be fitted into Structural Glazing systems

ULTIMA A1 NBS:

ULTIMA A2 NBS:

Technical

Downloads

ULTIMA Brochue

Technical Data Sheet

ULTIMA A1 Certification

ULTIMA A2 Certification

ULTIMA 3

Technical Drawing

Contact Us

Archives

Meta

Metalline (Services) Ltd,

Hollies Park Road,

Cannock,

Staffordshire,

WS11 1DB