ULTIMA Aluminium Insulated Spandrel Panels

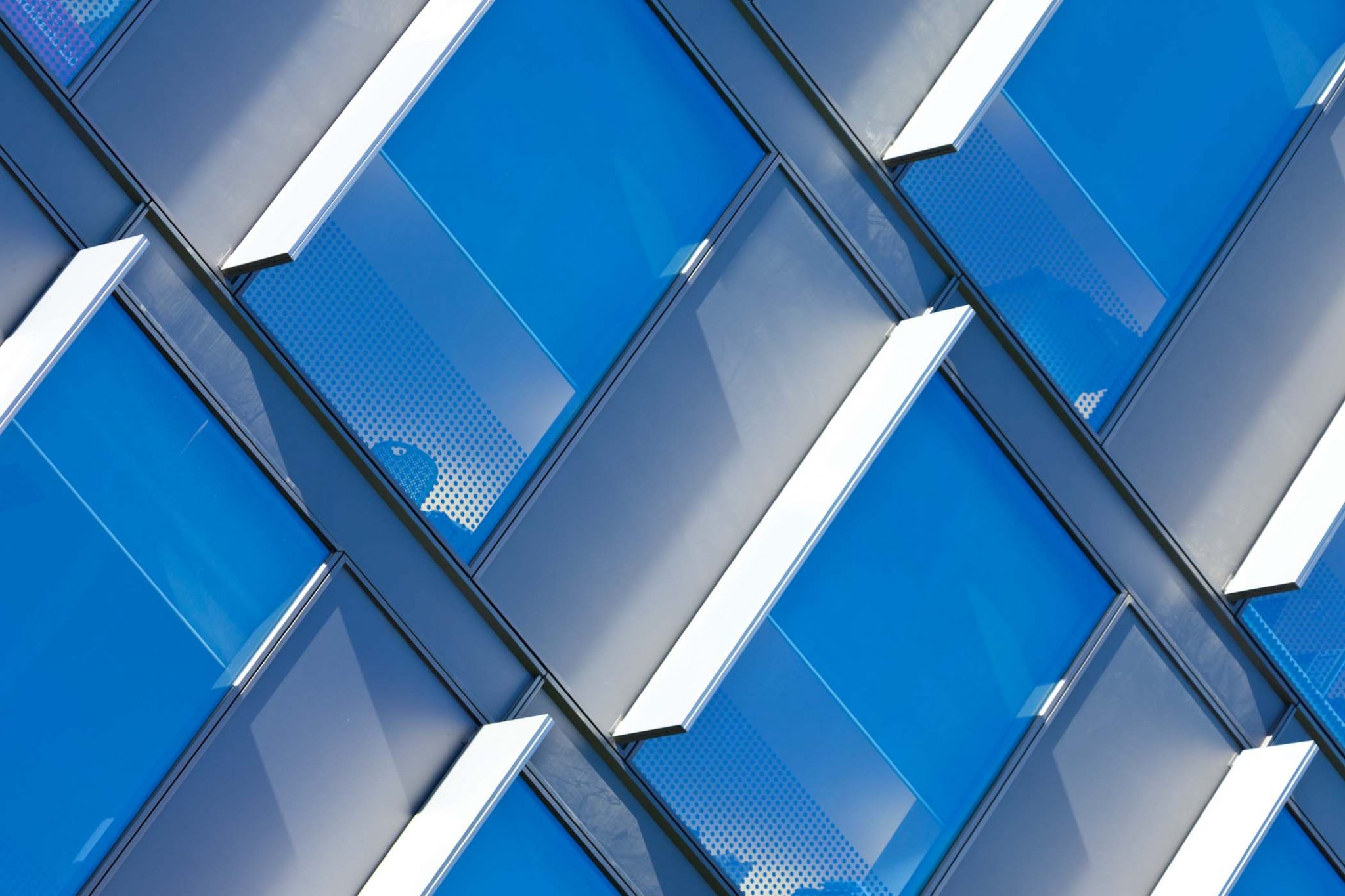

The ULTIMA aluminum insulated spandrel panel is the most tested spandrel panel on the market and offers high-performance solutions to construction projects requiring both technical excellence and aesthetic appeal.

Tested rigorously to BS EN13501-1 standards, ULTIMA spandrel panels can be manufactured to achieve either A1 or A2 – s1,d0 classifications, ensuring compliance with regulations regarding the use of non-combustible cladding. With the widest field of application on the market, ULTIMA panels offer designers the flexibility they require to meet specific project requirements while maintaining optimal fire performance and documented compliance.

Additionally, the ULTIMA range has been subjected to impact and wind resistance testing to CWCT standards, successfully meeting all designated criteria. Whether for new construction or cladding replacement projects, ULTIMA panels provide a versatile, compliant, and reliable solution.

Products

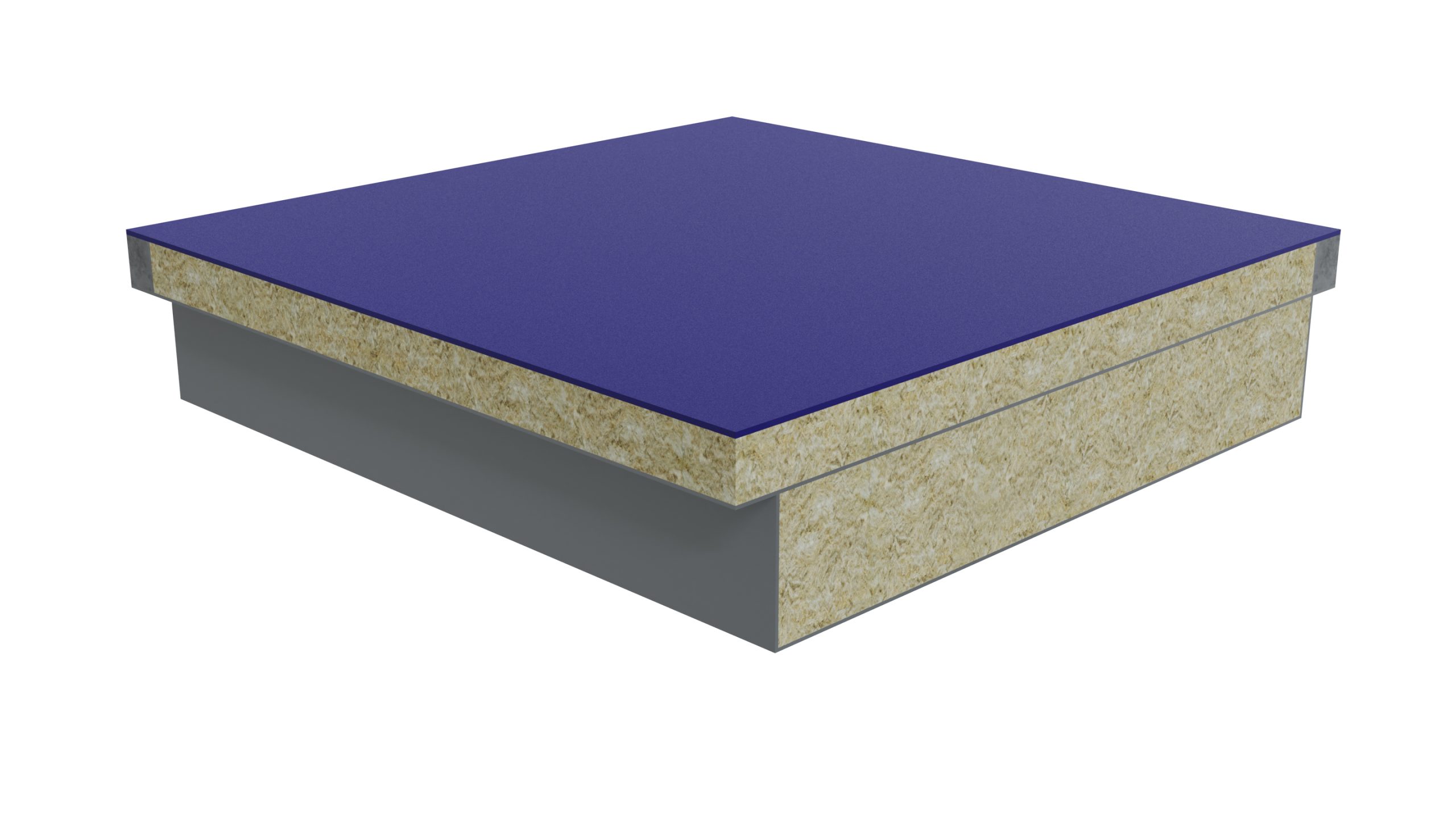

ULTIMA 1

ULTIMA 1 is an insulated spandrel panel crafted for adaptability, featuring a range of finishes to align with project specifications. The external layer boasts an aluminium tray available in anodised or PPC finish, adding a sleek and customisable aesthetic. The core is constructed with Fabrock Clad insulation, ensuring optimal thermal performance and flexibility in achieving desired ‘U’ values.

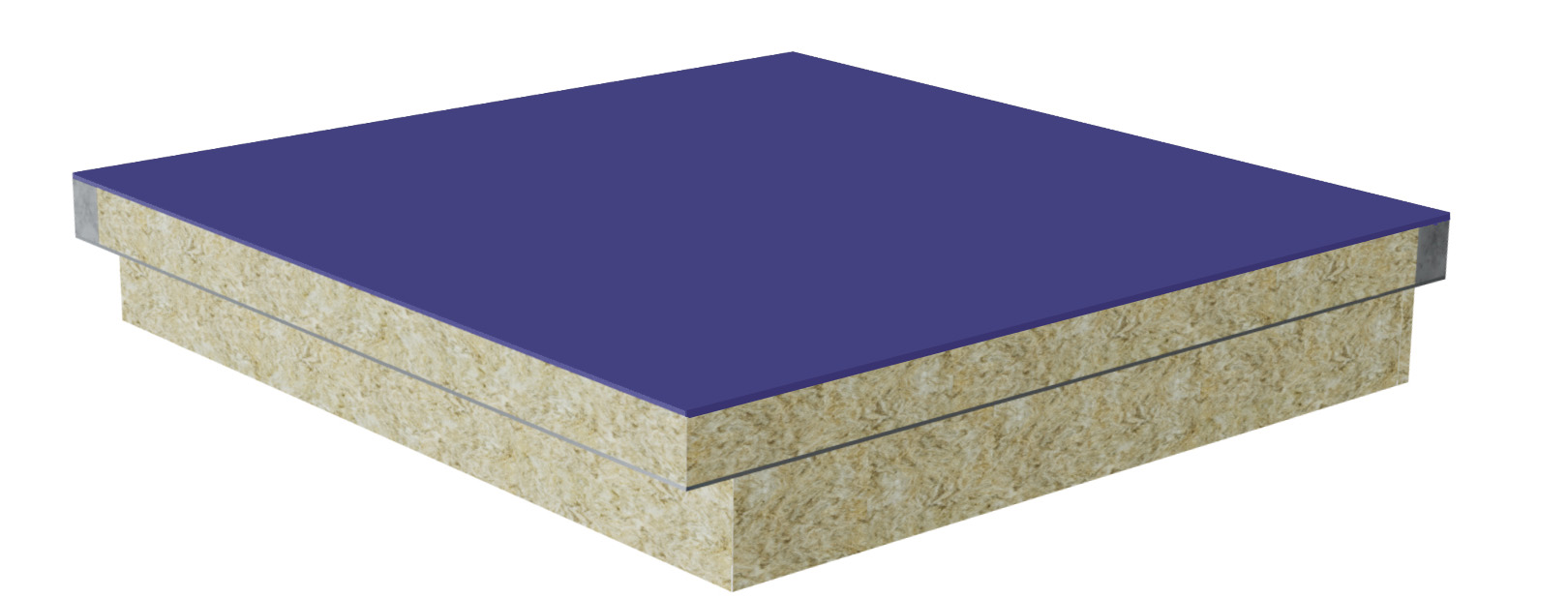

ULTIMA 2

ULTIMA 2, part of Metalline’s Insulated Spandrel Panel range, has achieved A1 and A2 – s1, d0 classifications according to BS EN13501-1, making it an ideal choice for new builds or replacing non-compliant Spandrel Panels. With limitless colour options, low maintenance requirements, and robust construction, ULTIMA 2 offers a cost-effective and aesthetically customisable solution.

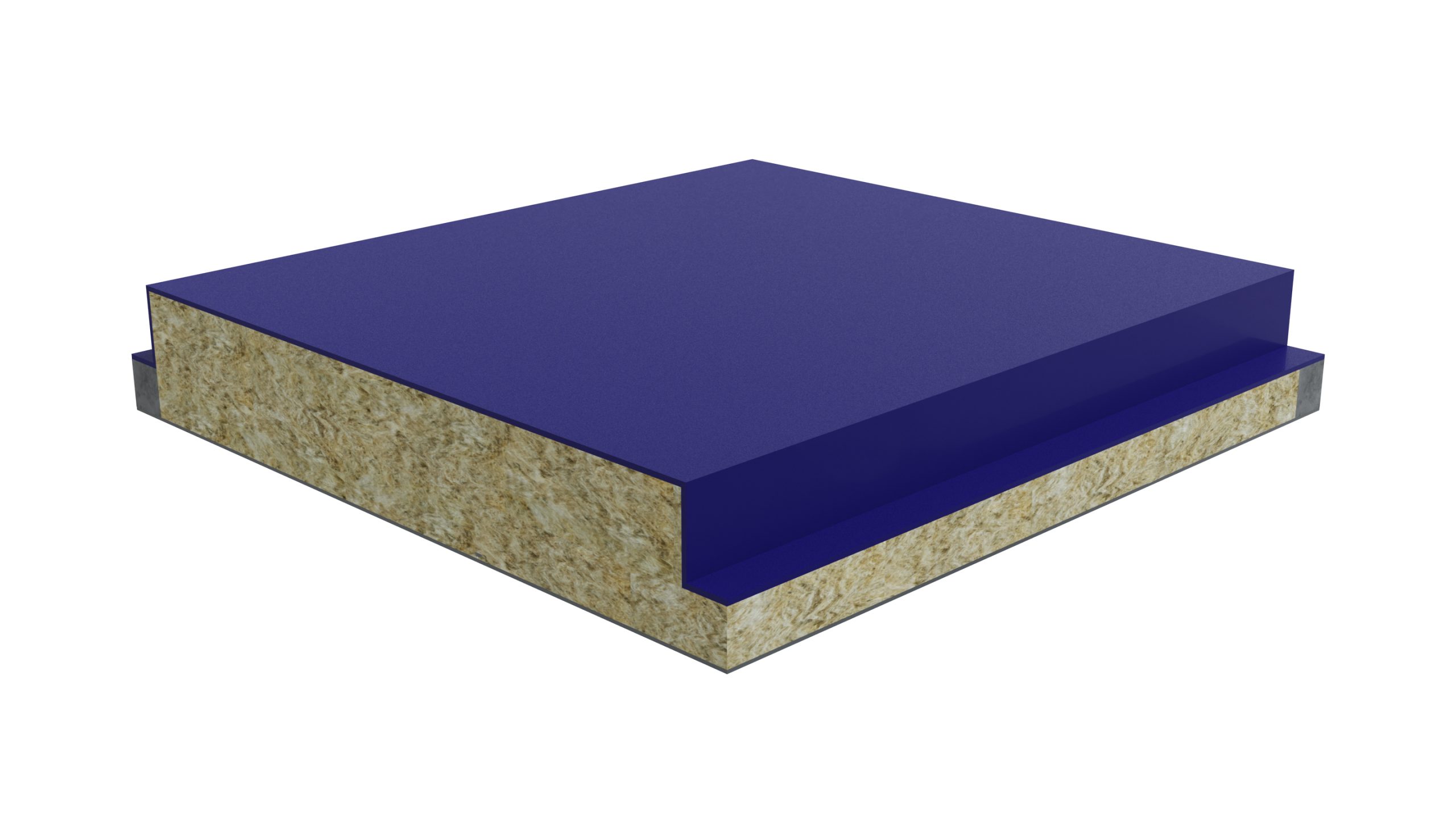

ULTIMA 3

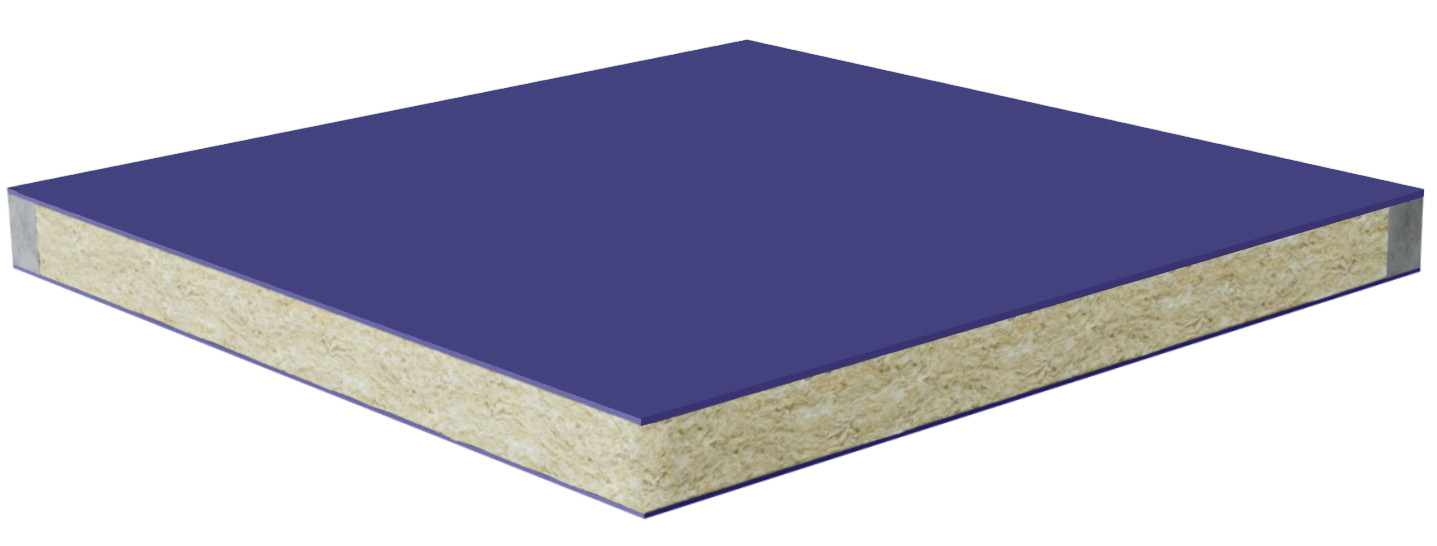

The ULTIMA 3 Insulated Spandrel Panel offers versatile finishes, allowing customisation based on classification requirements. The insulation thickness can be adjusted for desired ‘U’ values in your project. Externally, it features an aluminium tray with an anodised finish. The core comprises Fabrock Clad insulation, while internally, foil-faced Rockwool insulation is fitted to a galvanised steel/aluminium balancer sheet.

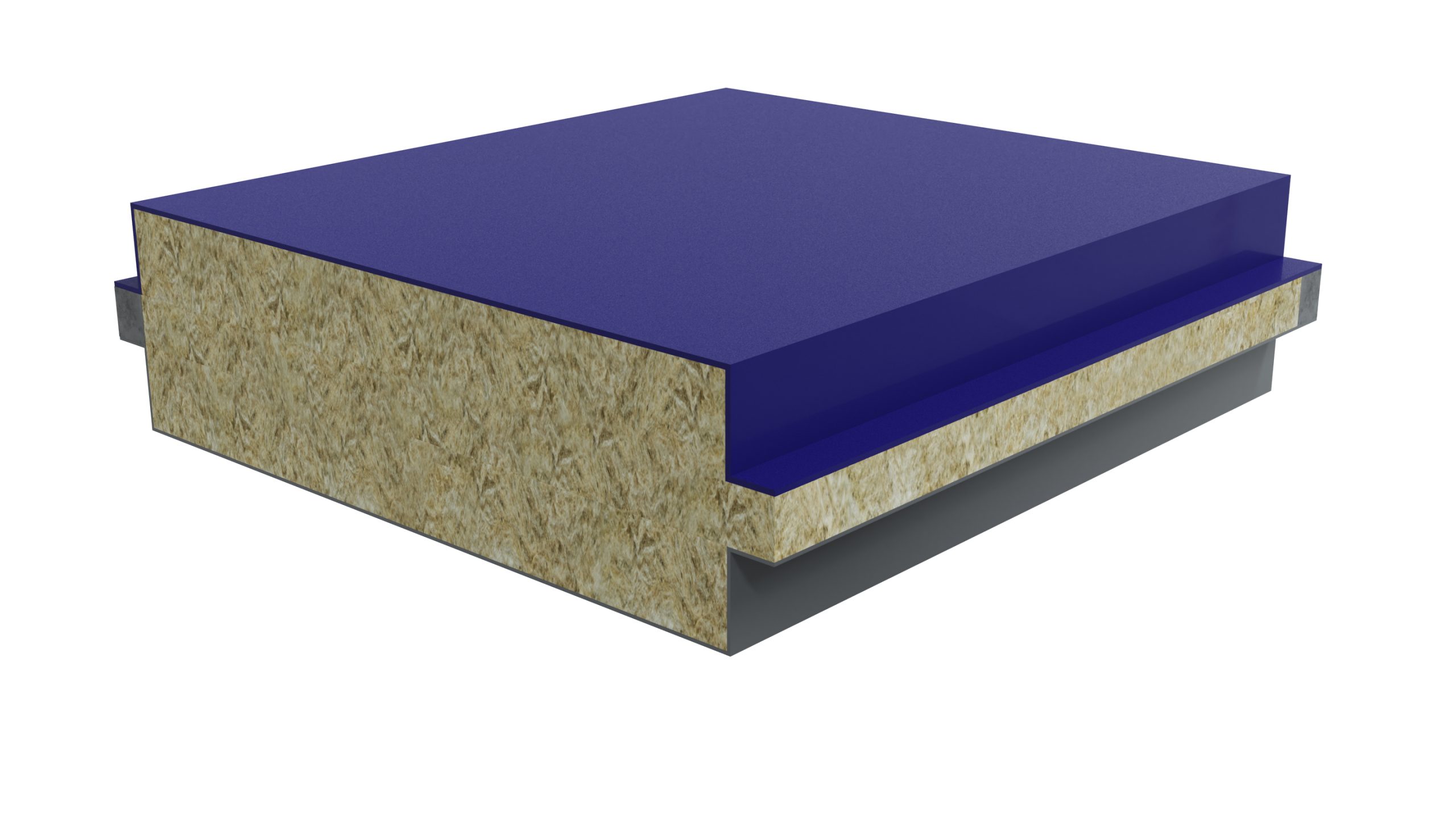

ULTIMA 4

ULTIMA 4, part of Metalline’s Insulated Spandrel Panel range, has undergone rigorous testing to BS EN13501-1, achieving both A1 and A2 – s1, d0 classifications. This makes it an excellent choice for new construction projects or replacing non-compliant Spandrel Panels. The external layer features an aluminium tray with the option of an anodised or PPC finish, providing a sleek and customizable exterior.

ULTIMA 5

ULTIMA 5, a part of the ULTIMA Insulated Spandrel Panel series, offers a versatile solution with customisable face finishes to match the required classification. The insulation thickness is adjustable to accommodate specific ‘U’ values for your project, making it a flexible choice. Featuring an external layer with an aluminium tray and anodised finish, ULTIMA 5 ensures a sleek and modern appearance.

Panels & Systems

Our ULTIMA range of spandrel panels are engineered so that each layer of the panel’s composition works together to produce a spandrel with outstanding mechanical properties, thermal efficiency and durability.

The ULTIMA panel is available in five different variants, each of which can be constructed to achieve either an A1 or A2-s1,d0 fire classification to EN13501. ULTIMA panels have been rigorously tested for both fire and structural performance making it the most tested panel in the industry. From a flat ULT 1 sandwich panel to an ULT 5 panel which incorporates a stepped tray to the inner and outer leaves, the ULTIMA range provides the flexibility designers require to meet specific project requirements.

Testing & Certification

ULTIMA aluminium insulated spandrel panels have been rigorously tested for both fire and structural performance. With the widest field of application on the market, ULTIMA panels have been tested to BS EN13501-1 and can be constructed to achieve either an A1 or A2-s1,d0 reaction to fire classification. With multiple material and finish combinations tested and covered with our certification, the ULTIMA panel provides designers with the widest scope within the market.

The ULTIMA A2 range of spandrel panels are vacuum bonded within a temperature and humidity-controlled factory. This ensures the thickness of adhesive is controlled to within the limits allowable under the BS EN13501-1 classification.

Each layer of the composite product has been tested to EN ISO 1716 in order to ascertain its GHC value. Panels are tested as a full unit to EN 13823 to determine their rate of heat release and production of smoke and flaming droplets.

Additionally, impact testing and wind resistance testing to CWCT standards (TN75/76) demonstrates the structural performance of the ULTIMA vacuum bonded panel and documents this within comprehensive technical reports.

Fire Performance

- DUMMY TEXT

- Fire Performance

A1 & A2-s1,d0 options available. - Field of Application

Widest scope of spandrel panel testing on the market

Structural Performance

- DUMMY TEXT

- Safety

Wind resistance testing to 3600Pa and 4500Pa

Finishes

Anodised Aluminium (A1 classification to BS EN13501-1) – All anodised finishes available with a lifetime finish warranty. Anodised finishes require little if any maintenance.

Powder Coated Aluminium (A2-s1,d0 classification to BS EN13501-1) – Powder coating offers a durable and versatile finish to an aluminium spandrel panel. Available in all RAL colours plus special finishes including woodgrain, stone and corten effect. Up to 40-year project specific coating warranties are available and maintenance will be required as part of the finish warranty.

To find out more about our finishes, please click here.

Gallery

Contact Us

Metalline (Services) Ltd,

Hollies Park Road,

Cannock,

Staffordshire,

WS11 1DB